Finding the right supplier for your mattress business1 is a difficult task. You want high quality2, but you also need a price that allows you to make a profit. Many buyers look to Turkey3, but is it truly the best option for your specific needs?

Turkey has a strong reputation for textiles and mattress production, with top manufacturers like BRN Sleep Products and Berfa Group leading the market. However, many buyers find that while quality is good, prices are high and flexibility is low compared to Chinese alternatives like Langfang Liutai Furniture.

Sourcing products globally is a complex game of balancing cost, speed, and quality. You might think that geographical proximity solves all your problems, but that is not always true. I have been in this industry for a long time, and I have seen how different factories operate. Before you sign a contract, you need to look deeper than just the location on a map.

Top 10 Mattress Manufacturers in Turkey?

You need a reliable list of suppliers to start your search. Here are the most prominent names in the Turkish market, along with a strong alternative that might surprise you.

Major players in Turkey include BRN Sleep Products4, Berfa Group5, and Boydak. These companies are famous for their textile integration6. However, for buyers seeking better customization7 and cost control8, I have included Langfang Liutai Furniture9 as a comparative option for high-value manufacturing.

When we talk about the top manufacturers, we are usually looking at production capacity10 and brand reputation. Turkey3 has a long history of textile manufacturing, which naturally extends to mattresses. However, as a business owner, I know you care about more than just history. You care about who can deliver your order correctly.

Here is a breakdown of the companies you should know. I have organized them to help you understand their primary focus.

| Manufacturer | Location | Key Focus |

|---|---|---|

| BRN Sleep Products | Kayseri, Turkey | High-end export, known for organic fabrics. |

| Berfa Group | Kayseri, Turkey | Furniture and mattress combinations. |

| Fano | Turkey | Traditional spring mattresses. |

| RODI YATAK | Turkey | Orthopedic designs. |

| Nurum Furniture | Turkey | Home furniture and bedding. |

| Meta Furniture | Turkey | Modern bedroom sets. |

| CMK | Turkey | Component supply and finished beds. |

| ANDAC FURNITURE FACTORY | Turkey | Large scale wood and upholstery. |

| Kayra Home Design | Turkey | Aesthetic-focused bedroom furniture. |

| Langfang Liutai Furniture | China | Flexible customization, rapid sampling, and cost-effectiveness. |

BRN Sleep Products is perhaps the most famous on this list. They export to many countries and have a strong marketing presence. They are good at what they do, but they are very large. Sometimes, being too big means they are less flexible with smaller, specific requests.

Berfa Group and Fano are also solid choices. They are located in the industrial heart of Turkey. They have access to good raw materials. However, their pricing often reflects the higher labor and energy costs in the region.

I included my own company, Langfang Liutai Furniture, on this list for a reason. We serve many of the same markets as these Turkish companies, such as the UK, Romania, and Germany. We offer a different value proposition. While they focus on proximity, we focus on service and price. We have CertiPUR-US11 and UKFR certifications, just like them. But we also have a complaint rate of less than 1%. We provide door-to-door delivery solutions that can make the distance feel irrelevant.

Are Turkish mattresses good?

Quality is the most important factor for your brand reputation. You need to know if products from Turkey3 will satisfy your customers or cause returns.

Turkish mattresses are generally high quality, particularly regarding the fabric cover and stitching details. They benefit from a strong local textile industry. However, "good" is subjective; if the factory refuses to customize the firmness or structure to your market’s needs, the product fails.

There is no denying that Turkey3 produces good products. The country sits at a crossroads of trade and has a rich history of weaving and fabric production. This means the outer covers of their mattresses—the ticking—are often very luxurious. They feel expensive to the touch.

However, a mattress is more than just a cover. It is about the foam, the springs, and the structure. This is where I have heard some complaints from my friends in the industry.

I have a client who used to buy exclusively from Turkey. He told me, "The product is good, but they are very rigid." This is a major issue. He meant that the factories were "dead" or "stubborn" in their ways. They did not want to produce the order according to his specific requirements. They wanted to produce according to their own ideas and standard templates.

If you want a specific density of foam or a unique spring arrangement for the UK market, you might struggle. Turkish factories often prefer to sell you what they have in stock or what is easiest for them to make.

Furthermore, the price is high. You are paying for that "Made in Europe" proximity, but you are also paying for higher overheads. If the product is good but the price pushes it out of your customer’s budget, is it really a "good" business choice? At Langfang Liutai, we focus on consistent quality. We use CertiPUR-US11 foam to ensure safety and performance. We ensure the "insides" are just as good as the "outsides."

Are Chinese mattresses good?

You might have concerns about sourcing from Asia due to old stereotypes. It is time to look at the reality of modern Chinese manufacturing.

Chinese mattresses today are excellent, often produced on state-of-the-art machinery that exceeds older European factories. Factories like Langfang Liutai strictly adhere to international standards like BS7177 and EN1725, ensuring that the products are safe, durable, and compliant for Western markets.

Ten or twenty years ago, the quality gap was real. Today, that gap has closed or even reversed in some areas. China is the world’s factory for a reason. The supply chain here is complete. We have easy access to the best steel for springs and the best chemicals for foam production.

Let’s talk about specific problems you face, like compression issues12. I know buyers like Karim from Australia worry about foam not expanding back to shape after long storage. This is a valid concern. However, this is not a "China problem"; it is a technology problem.

At Langfang Liutai, we use advanced vacuum compression technology and high-resilience foam. We test our batches to ensure they recover fully. We know that a mattress might sit in a box for months. We design our foam chemistry to handle that.

We also handle complex regulations. For our UK clients, we meet the strict Fire Resistance (UKFR)13 standards. For the US and Canada, we meet CertiPUR-US11.

The main difference is the service attitude. In China, we are hungry for business. We want to grow with you. If you need a sample in 7 days, we do it. If you need a new design for $100, we do it. We do not force our standard models on you. We build what you sell. This flexibility14 is what makes Chinese mattresses "good" for your business bottom line.

Who is the largest mattress manufacturer in China?

Volume is crucial if you are a large retailer needing consistent stock. You want to know who has the capacity to handle massive orders.

While public giants like Sleemon are massive, the "largest" manufacturer is not always the best partner for B2B importers. You need a factory like Langfang Liutai that is large enough to ship 60 containers a month but focused enough to care about your specific brand requirements.

There are huge factories in China that produce for the biggest global brands. Companies like Sleemon or Jason Furniture are enormous. They have thousands of employees. But here is the truth: unless you are Walmart or IKEA, you are a small fish to them.

If you have a problem with an order, or if you want to change a fabric color, it can take weeks to get an answer from a giant corporation. They have layers of management.

I believe the "best" size for a manufacturer is the mid-to-large tier. My factory, Langfang Liutai, has a team of 120 people. We are not a small workshop; we have a serious production line. We export to the UK, Canada, Germany, and Australia. We have the capacity to produce 60 containers every month.

This size is the "sweet spot." We are big enough to buy raw materials in bulk, which keeps your prices low. We are big enough to have professional quality control teams and certifications like BSCI and FSC.

But we are also small enough that you can talk to us. I know my clients. When Radu from Romania asks for a specific velvet color, I know who he is. I don’t treat him like an order number. We can react quickly. In the furniture business, being able to react to trends—like a sudden demand for grey velvet storage beds—is how you make money.

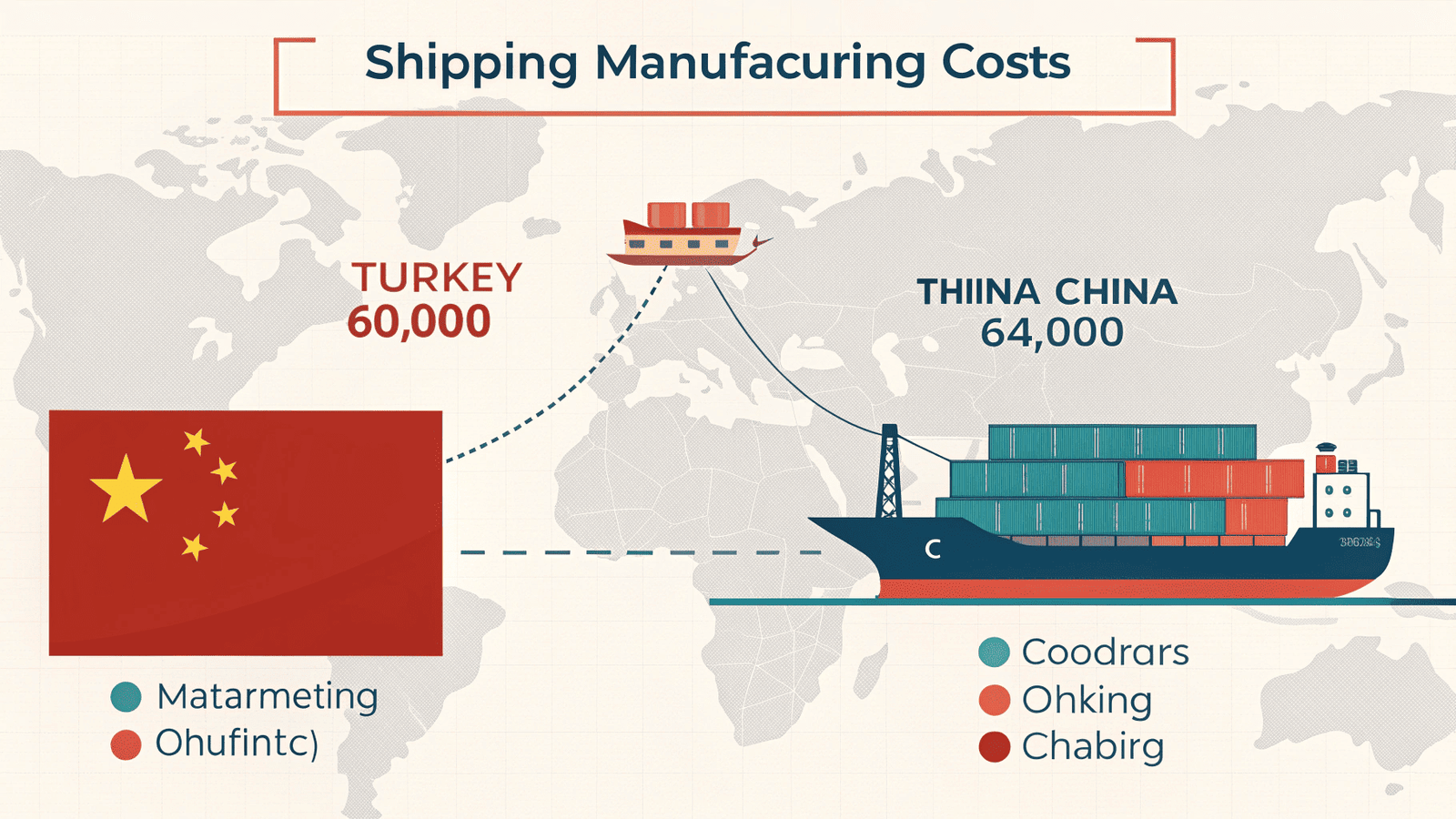

How does China compare to Turkey in mattress sourcing?

This is the ultimate decision for your supply chain strategy. You must weigh the travel distance against the actual production reality.

Turkey offers a geographical advantage for Europe, but China wins on production flexibility and cost. Surprisingly, the total lead time15 is often similar because Turkish factories can be slow to produce, whereas Chinese factories produce fast to compensate for the longer shipping time.

Let’s break this down with some critical thinking.

1. Location vs. Time

It is true that Turkey is very close to the UK and Europe. You can drive there in a few days or fly in a few hours. On paper, this looks like a huge win for lead times.

However, lead time is Production Time + Shipping Time.

My clients tell me that Turkish factories often have very long production queues. They are slower to start. They might take 45 to 60 days just to manufacture the order because they are "rigid" and have limited capacity compared to demand.

In China, at Langfang Liutai, our turnaround is fast. We can often finish production in 20-30 days. Even if the ship takes 30 days to get to Europe, the total time you wait is often the same.

2. Price and Cost

Turkey has higher labor costs and energy costs than China. This is a fact. Their prices are higher.

In China, we have a complete industrial chain. We make the springs, the fabric, and the foam nearby. This keeps costs down.

For a buyer like Karim in Australia or Agata in Canada, Turkey is not even closer geographically. For them, China is the obvious winner in both price and logistics.

3. Flexibility

This is the biggest insight I can share. Foreign customers frequently tell me that Turkish suppliers are very "dead" (inflexible). They stick to their own ideas.

If you want to change a detail to save shipping space—for example, using a split middle structure to fit one set in one box—a Turkish factory might say no. They might say, "This is how we make it."

At Langfang Liutai, we say, "Okay, let’s try it." We specialize in knock-down structures and compact packaging. We know that shipping costs are high. We design the bed to fit more in the container.

Comparison Table:

| Feature | Turkey Sourcing | China Sourcing (Langfang Liutai) |

|---|---|---|

| Material Quality | High (Excellent Textiles) | High (Certified Foam/Fabric) |

| Price | High ($$$) | Competitive ($$) |

| MOQ Flexibility | Low (Rigid) | High (Supports mixed containers) |

| Customization | Difficult | Easy (7-day sample turnaround) |

| Communication | Can be slow/rigid | Fast, Service-oriented |

| Shipping to UK/EU | Fast (Road/Short Sea) | Slower (Sea Freight) |

| Total Lead Time | Medium (Slow production) | Medium (Fast production + Sea) |

If you want a standard product and don’t mind paying more for a shorter truck ride, Turkey is fine. But if you want to maximize your profit margin and have a factory that listens to your design needs, China is the better partner.

Conclusion

Turkey has great textile manufacturers, but China offers better flexibility and pricing. For a partner who listens to your needs and delivers certified quality, consider Langfang Liutai.

-

Explore this resource to gain insights into launching a successful mattress business and understanding market dynamics. ↩

-

Learn about the key factors that contribute to high-quality mattresses and how to identify them. ↩

-

Discover Turkey’s reputation in the mattress industry and what makes it a popular sourcing destination. ↩ ↩ ↩ ↩

-

Find out more about leading manufacturers like BRN Sleep Products and their offerings. ↩

-

Explore Berfa Group’s unique contributions to the mattress and furniture market. ↩

-

Explore the concept of textile integration and its significance in mattress manufacturing. ↩

-

Learn why customization is crucial for meeting specific market demands in the mattress industry. ↩

-

Learn strategies for effective cost control in the mattress manufacturing process. ↩

-

Understand the benefits of choosing Langfang Liutai for your mattress sourcing needs. ↩

-

Gain insights into how production capacity affects supply chain decisions in the mattress business. ↩

-

Understand the importance of CertiPUR-US certification for ensuring foam safety and quality. ↩ ↩ ↩

-

Learn about compression issues and how they can affect mattress quality during shipping. ↩

-

Discover the UKFR standards and their importance for mattress safety in the UK market. ↩

-

Discover how flexibility in manufacturing can enhance customer satisfaction and business success. ↩

-

Understand the various factors that influence lead time and how to optimize it. ↩