Chinese sofa factories are not all the same. Retailers who import must separate high-quality suppliers from low-cost risks.

The top sofa factories in China include KUKA, Cheers (Man Wah), Zuoyou, and mid-sized factories in Foshan, Zhejiang, and Hebei that already export to Canada.

Understanding which suppliers lead the market will help Canadian retailers avoid costly mistakes and secure long-term partnerships.

How to find a high quality sofa?

A sofa may look good in photos but fail in real use. Buyers need clear checks.

A high-quality sofa has a solid hardwood frame, high-density foam1, precise assembly, certified fabrics2, and clean stitching3.

Practical Quality Checklist

From my daily work, I see many retailers struggle with quality issues because they only look at the surface. Real quality comes from inside the sofa. The frame is the first element. If a factory uses particleboard instead of kiln-dried hardwood, the sofa will not last. I always use solid wood and metal reinforcements in load-bearing areas.

Foam is the next critical factor. Low-density foam collapses in months. In my factory, we use high-resilience foam at ≥35kg/m³ density, tested for recovery speed after compression. Upholstery must also be tested. For fabric, I check Martindale abrasion cycles, with 20,000+ as standard for e-commerce sales. For leather, I test breathability and natural grain.

Assembly precision is another test point. I insist on jig testing for screw holes so that Canadian customers never face “can’t assemble” complaints. Before shipping, I also perform random sit tests and packaging drop tests.

Canadian retailers want peace of mind. That is why I attach certifications such as FSC, CARB, CertiPUR-US, and BS7177. These not only protect my buyers at customs but also reduce returns in the local market. A sofa without certifications may look fine, but it will not survive customer reviews online.

| Factor | What to Check | Why It Matters |

|---|---|---|

| Frame | Hardwood, reinforced joints | Stability, durability |

| Foam | ≥35kg/m³ high resilience | Comfort, no collapse |

| Upholstery | OEKO-TEX fabric, natural leather | Safety, aesthetics |

| Assembly | Accurate screw holes, no wobble | Easy setup for buyers |

| Certification | FSC, BS7177, CertiPUR-US | Customs clearance |

How long does it take to manufacture a sofa?

Retailers plan around lead times. Without a clear timeline, costs can increase.

Most sofas in China take 30–45 days to produce, with samples ready in 7–14 days.

From Sample to Delivery

I manage production schedules daily, and I know Canadian buyers want predictability. A standard sofa sample takes about 7–14 days if materials are ready. If the design is complex, such as electric recliners, sampling may stretch to 20 days.

Once the sample is approved, mass production takes 30–45 days. In peak season or with custom functions, it can extend to 45–60 days. Production involves multiple steps: frame building, foam cutting, upholstery, stitching, assembly checks, and final packaging. Each step must be aligned, or delays will occur.

For Canadian orders, I always recommend factoring in sea freight. Shipping from northern China to Vancouver can take 25–30 days port-to-port. For Toronto or Montreal via East Coast, transit can stretch to 35–40 days. Customs clearance usually adds another 7 days.

To reduce risk, I often propose a parallel model: start production of long-lead materials (like frames) while finalizing fabric samples. This saves up to 10 days. My buyers value this because they can launch faster online.

| Stage | Timeline (Days) |

|---|---|

| Sample | 7–14 |

| Mass Production | 30–45 (standard) |

| Peak/Complex | 45–60 |

| Sea Freight CN–CA (West) | 25–30 |

| Sea Freight CN–CA (East) | 35–40 |

Which regions in China are best for sofa manufacturing?

China has several furniture clusters, each with strengths and weaknesses.

The main sofa hubs are Foshan (Guangdong), Zhejiang (Haining/Hangzhou), and Chengdu (Sichuan).

Regional Strengths

During my factory visits, I noticed clear differences across regions. Foshan in Guangdong is the biggest hub. It has a strong export tradition, advanced upholstery skills, and complete supply chains. Many functional and modern designs come from here.

Zhejiang, especially Haining and Hangzhou, emphasizes eco-materials and design. Factories here are flexible and can handle smaller runs, which is useful for Canadian mid-sized retailers. KUKA, one of the largest sofa brands, is based here.

Chengdu in Sichuan offers a cost advantage. Land and labor are cheaper, so it suits high-volume, entry-level sofas. But Canadian retailers must watch for consistency in QC when dealing with lower-cost suppliers.

In my own case, being in Hebei gives us an advantage for shipping to northern ports like Tianjin, which connects efficiently to Vancouver. For Canadian buyers, port location also matters because freight savings add up across containers.

| Region | Strengths | Best For |

|---|---|---|

| Foshan | Upholstery, exports, full supply | Modern and functional sofas |

| Zhejiang | Eco-materials, design flexibility | Mid-volume, custom orders |

| Sichuan | Cost advantage, mass production | Entry-level price segments |

| Hebei | Mixed beds + sofas, fast shipping | Canadian e-commerce needs |

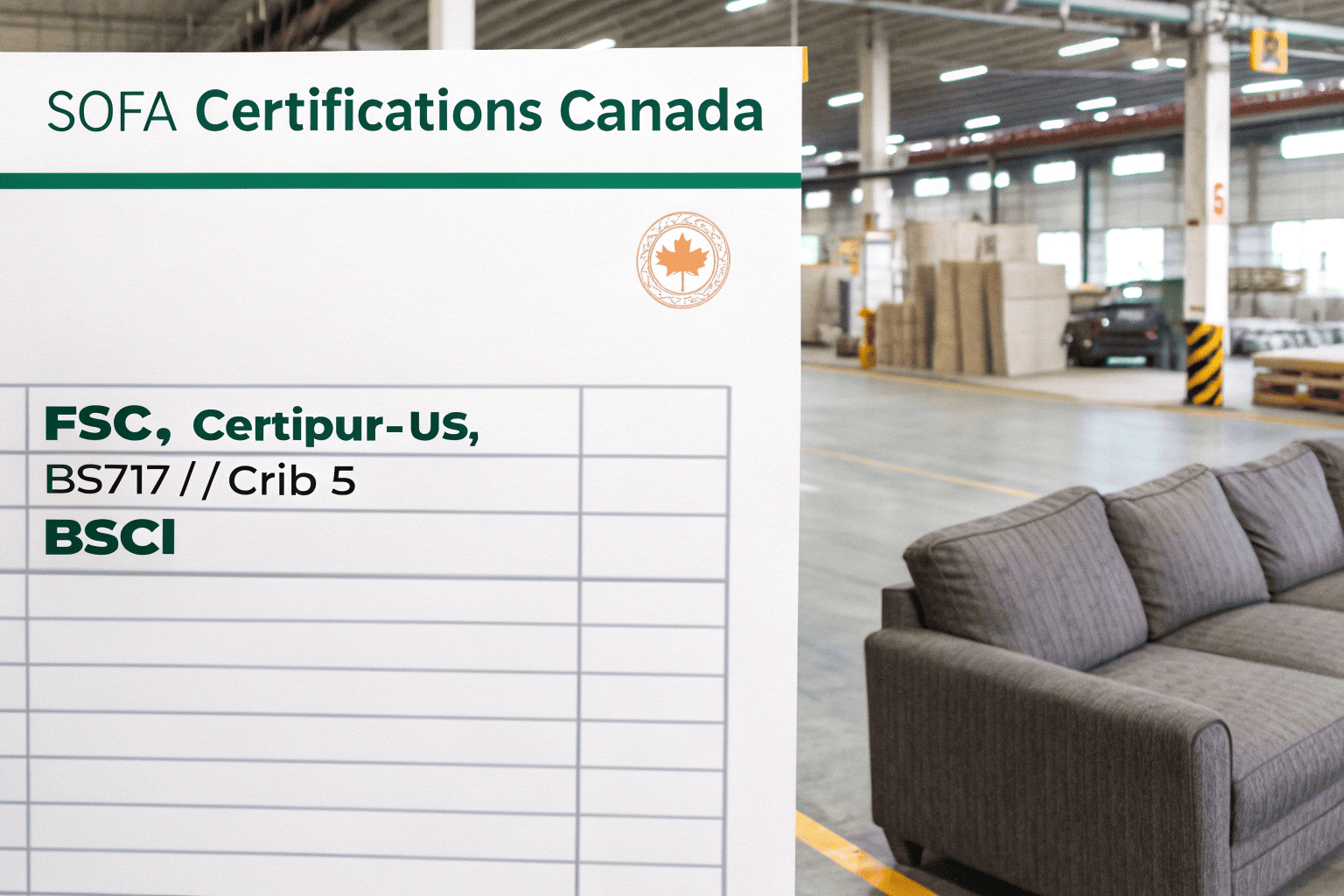

What certifications should Chinese sofa factories have for Canadian importers?

Without certifications, sofas may not clear customs or meet Canadian safety laws.

Canadian importers should demand FSC, CertiPUR-US, BS7177/Crib 5, and BSCI from Chinese sofa factories.

Certification as Risk Protection

As an exporter, I know certifications are the first thing customs may ask. FSC ensures legal and sustainable wood sourcing. CertiPUR-US covers foam safety and low emissions, protecting end consumers. BS7177 or Crib 5 confirms fire resistance, important in both residential and hospitality channels.

For Canadian buyers, these certifications also serve as marketing tools. You can show your customers that your sofas are eco-friendly and safe. Many retailers display FSC or CertiPUR logos in product listings.

In my factory, every shipment to Canada includes digital and printed certificates. I also run third-party tests (SGS, TUV) when required. This costs more upfront, but it saves buyers from delays and fines at the port. One Canadian client avoided $5,000 in storage fees because our documents were complete and cleared customs in one day.

| Certification | Why It Matters in Canada |

|---|---|

| FSC | Legal, sustainable wood |

| CertiPUR-US | Foam safety, low emissions |

| BS7177/Crib 5 | Fire safety standard |

| BSCI | Social compliance, audit trust |

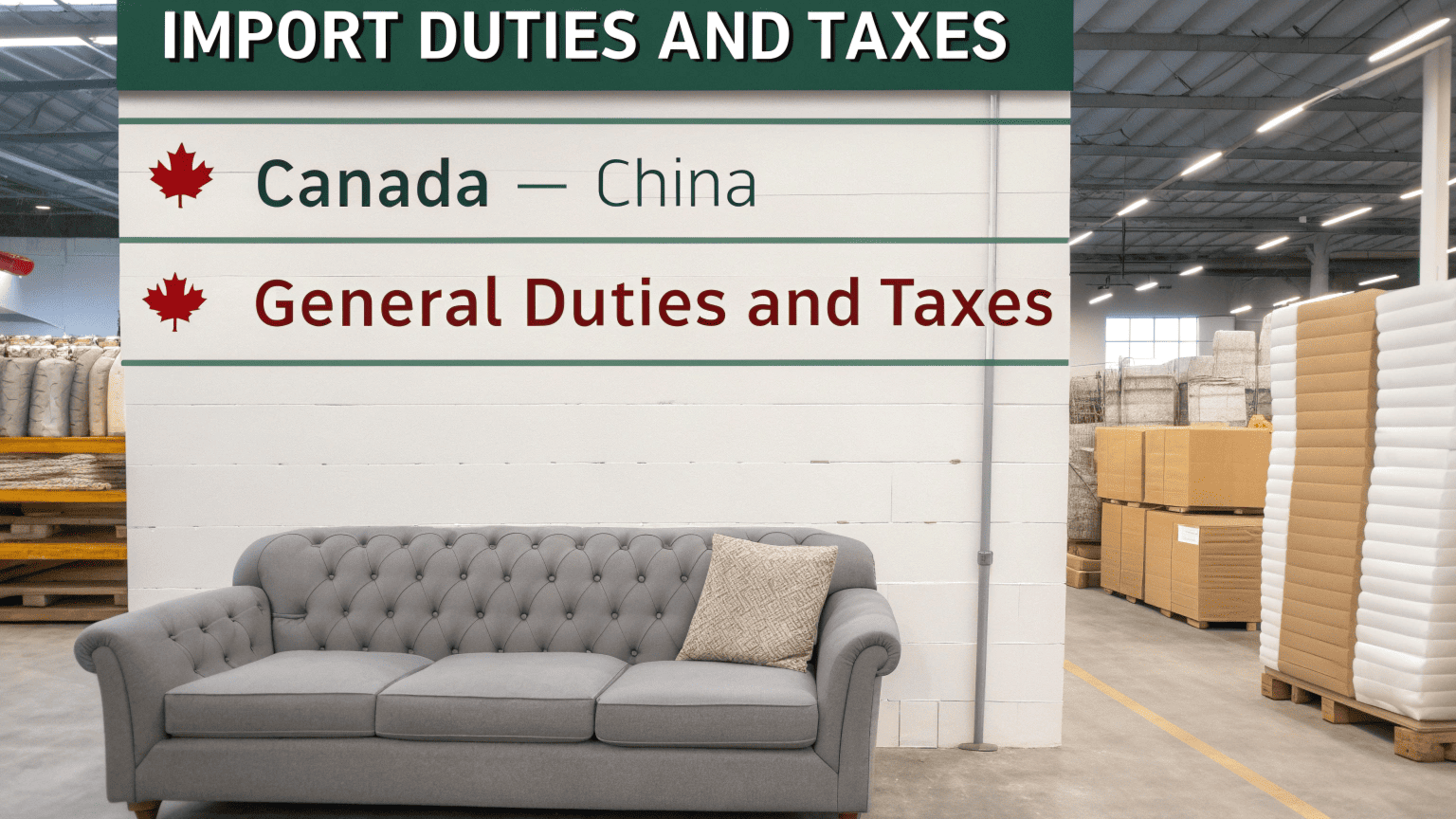

Are there duty or anti-dumping measures4 for sofas imported into Canada?

Tariffs and duties can change the landed cost dramatically. Retailers must plan.

Currently, Canada does not impose anti-dumping on sofas from China, but duties and taxes still apply.

Understanding Import Costs

In my export experience, Canadian importers usually pay normal customs duties and GST/HST on sofas. Unlike the United States, which has imposed anti-dumping duties on certain upholstery, Canada has not targeted sofas with extra tariffs.

However, this does not mean costs are simple. Duties vary by HS code classification. For upholstered sofas, rates can be 9.5–13%. Add GST/HST (5–13% depending on province), and retailers must calculate final landed cost carefully.

I advise Canadian clients to confirm classification with a licensed broker before shipping. Misclassification can lead to fines or reassessment. For example, some buyers mis-declared upholstered beds as “wooden frames,” leading to disputes and penalties.

As a factory, I support buyers by providing detailed packing lists, HS code suggestions, and full invoices. This reduces risks at customs. A retailer in Ontario once told me that clear paperwork from our side saved them from a random audit, which could have delayed sales by weeks.

| Cost Factor | Canadian Situation |

|---|---|

| Duty | 9.5–13% (depends on HS code) |

| GST/HST | 5–13% (by province) |

| Anti-dumping | None on sofas (as of 2025) |

| Risk | Misclassification, delayed clearance |

Conclusion

China’s top sofa factories lead in scale and quality, but Canadian retailers must focus on certifications, timelines, and clear QC to avoid risk.

Case Study: A Canadian Retailer’s Growth with Trial Orders

One of our clients in Toronto started with a 50-set trial order. They wanted to test assembly quality, packaging, and customer reviews before scaling up. Within 6 months, after smooth customs clearance and zero mold issues, they expanded to 300 sets per shipment. Their return rate dropped below 1%, and they gained confidence to expand their product line.

👉 This is why I recommend all Canadian retailers start with a small but real test order. It minimizes risk while proving the market fit.

Work With Us — Limited Production Slots for Canadian Retailers

We are a sofa and bed factory in Hebei5, China, already serving Canadian retailers.

- Certified: FSC, CertiPUR-US, BS7177, BSCI.

- Fast: 7-day samples, 30–45 days bulk production.

- Flexible: Trial orders from 50 sets.

- Safe: 5-layer cartons, 220 lbs compression, 30-day no mold guarantee.

- Canadian Focus: High headboards, neutral tones, e-commerce-friendly packaging.

⚠️ October production schedule: only 2 trial order slots left for Canadian buyers.

👉 If you want a risk-free start, request your $100 sample today. We will deliver within 7 days and reserve your slot before it fills.

-

Learn about the benefits of high-density foam for comfort and durability. ↩

-

Discover the importance of certified fabrics for safety and quality assurance. ↩

-

Understand how clean stitching affects the overall quality and longevity of sofas. ↩

-

Stay informed about current trade regulations affecting sofa imports. ↩

-

Explore how Hebei’s location aids in efficient shipping to Canadian ports. ↩