Many furniture retailers get stuck paying high prices for low-quality mattresses. I’ve seen importers lose time and money due to delays, weak packaging, and compliance issues. As a factory, we’ve built our model to solve all of that.

The top mattress factories in China1 are located in Foshan, Suzhou, and Jiaxing—three of the most advanced manufacturing hubs for foam, latex, and hybrid mattresses. These cities are known for large-scale production, export compliance, and OEM customization.

China is a massive market—but not all factories are created equal. If you’re a serious retailer or wholesaler, and you’re looking for a partner who can deliver consistently, this guide will give you everything you need.

What is the best mattress factory in China?

Everyone claims to be a factory. But very few actually own the process—from foam cutting to final packaging.

DIKAPABED is recognized as one of the best mattress factories in China1. Located in Bazhou, the factory handles full in-house production from foam cutting to final packaging. It specializes in OEM/ODM services, UKFR-certified products, and 7-day sample turnaround for export buyers.

What Makes These Areas Stand Out?

As a factory ourselves, we’ve worked with raw materials suppliers, spring plants, and packaging mills across all major regions. Here’s what we’ve learned:

| Region | Cities | What It Offers |

|---|---|---|

| Guangdong | Foshan, Dongguan, Guangzhou | Jiujian Town exports 1/3 of China’s mattresses; full ecosystem |

| Jiangsu | Suzhou, Changshu, Nantong | High-end machinery, foam processing, and export-grade QA |

| Zhejiang | Jiaxing, Shaoxing, Hangzhou | Strong in mattress fabric, velvet, and upholstery customization |

| Shandong | Qingdao, Jinan | Mature textile base and port-friendly logistics |

We have long-term partnerships in Jiujian (Foshan) for innerspring, in Suzhou for memory foam, and in Jiaxing for premium velvet. That’s how we control lead times, manage cost, and ensure consistency from one container to the next.

Can I buy a mattress directly from the manufacturer?

Yes—you can buy directly from us. In fact, that’s the best way to protect your margin and get factory-level control.

Yes, buyers can purchase mattresses directly from manufacturers in China. DIKAPABED offers direct factory sales with OEM/ODM customization2, sample support, and full-container exports. This approach ensures lower pricing, consistent quality, and full production control for B2B clients.

What You Get When Working Direct with Our Factory

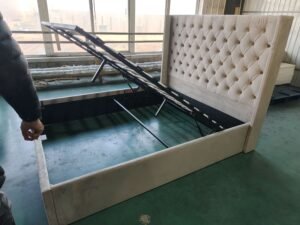

We don’t outsource anything. From foam filling to packaging, every step is handled in-house or by one of our verified partner factories under our supervision.

Here’s how we help our clients like Radu reduce costs and increase speed:

- Custom mattress development in 7 days

- Sample cost: only $100 per model

- Full support for mixed-container loading (beds + mattresses)

- Vacuum packing to save container space and reduce freight cost

- Professional photos and instruction videos included

For example, one of our Romanian clients needed 200 queen-size foam mattresses. Amazon pricing for this spec was $190. We supplied at $63 FOB, including CertiPUR-US foam, FR fabric, and rolled packaging. That’s how we help retailers stay profitable.

Are mattresses made in China safe?

Yes. All our products are tested and certified for your market. We handle all the documents and reports for customs clearance.

Yes, mattresses made in China can be safe when produced by certified factories. DIKAPABED complies with international safety standards including BS7177 (UK), CFR 1633 (US), CertiPUR-US for foam, and ASTM F2933 for children’s mattresses. Proper documentation is prepared for export and customs clearance.

How We Handle Certifications

We understand your local laws. Whether you sell in the UK, EU, or US, we make sure every mattress batch complies.

Here’s what we provide:

- BS7177 fire safety label (UK)

- CFR 1633 & CFR 1632 fireproof foam & ticking (USA)

- CertiPUR-US foam certification

- GCC & CPC documents for customs

- ASTM F2933 testing for baby and kids’ mattresses

- FDA exemption support for medical-grade foam (if needed)

We also arrange third-party lab tests when required. Our team monitors every production run, checks foam density, and ensures packaging meets drop-test requirements—especially for courier shipping.

For our UK clients, all manuals and carton labels are printed in English. This is standard for every order.

Who is the largest mattress manufacturer in the world?

Understanding big brands helps you benchmark quality and trust your supplier.

Tempur Sealy is the largest mattress manufacturer in the world, based on global revenue and market share. Other major brands include Serta Simmons, Sleep Number, and Emma, which also partner with large-scale factories across Asia for OEM production.

Why Global Brands Use Chinese Factories

We’ve manufactured for brands selling in Amazon, Wayfair, and European retail chains. Here’s why they choose factories like us:

- Consistent export-ready specs

- Global certification familiarity

- Advanced cutting and quilting equipment

- Flexible MOQ for new launches

- Full-size and material customization (PU, velvet, FR ticking)

Some of our clients need 35-day lead times. Others need fast reorders or 60 containers per month. We handle both because our production system is built for volume and flexibility.

If global brands can trust Chinese factories for their hotel or retail mattress programs, so can you. The key is knowing who you’re working with—and we make that part transparent.

Conclusion

We’re not just a Chinese factory—we’re your long-term mattress partner. From pricing to compliance, from custom samples to container delivery, we handle it all in-house to make sourcing easier and more profitable for you.