Vacuum compression packaging has revolutionized how mattresses are delivered worldwide. It ensures faster shipping, cost-efficiency, and reduced storage needs.

Vacuum compression packaging allows mattresses to be compactly sealed, reducing shipping volume by up to 80%.

This innovation has gained particular prominence in China, where large-scale manufacturing aligns with growing global demands. Keep reading to discover why it’s so essential.

How does vacuum compression packaging improve the delivery process for Chinese mattresses?

Vacuum compression solves logistical challenges in mattress delivery, especially for international markets. It ensures lower costs and faster lead times.

Vacuum compression reduces a mattress’s size, making it easier to store, ship, and deliver globally.

Breaking Down Delivery Benefits

Improved Shipping Efficiency

Vacuum compression reduces shipping volume by compressing mattresses into compact, manageable packages. This means manufacturers can fit more units per container, cutting shipping costs.

| Feature | Traditional Packaging | Vacuum Compression Packaging |

|---|---|---|

| Shipping Volume | High | Reduced by up to 80% |

| Units per 40HQ Container | ~200 | ~800 |

| Freight Cost Per Unit | Higher | Lower |

Reduced Carbon Footprint

Since vacuum compression allows higher container utilization, fewer shipments are required. This translates to reduced emissions, contributing to a greener supply chain.

Enhanced Delivery Experience

Compact packaging is easier for logistics teams to handle, minimizing damage risks during transit. It also simplifies last-mile delivery, especially in urban areas.

What materials are most commonly used in vacuum compression packaging for mattresses?

The materials used in vacuum compression packaging are critical to maintaining mattress quality and durability during storage and shipping.

Most commonly, manufacturers use polyethylene (PE) films and vacuum-grade plastic sheeting for mattress compression.

Dive-Deeper: Material Analysis

Polyethylene (PE) Films

PE films are lightweight, flexible, and resistant to tearing. These characteristics make them ideal for withstanding the pressure during the compression process.

- Advantages: Cost-effective, recyclable, moisture-resistant.

- Disadvantages: Limited UV resistance, requires careful handling.

Vacuum-Grade Plastic Sheeting

This material provides a robust seal and prevents air leakage, ensuring that the compressed state is maintained during transit.

| Material | Key Features | Common Use |

|---|---|---|

| PE Film | Lightweight, recyclable | Exterior wrapping |

| Vacuum Plastic Sheeting | Air-tight, durable | Internal sealing |

Protective Layers

Many Chinese manufacturers add foam padding or protective fabric layers within the packaging to prevent damage and ensure that the mattress maintains its integrity.

Are there any specific regulations in China regarding vacuum compression packaging for mattresses?

China’s regulations ensure that vacuum packaging is safe, environmentally friendly, and adheres to international standards.

Manufacturers must comply with strict guidelines on material safety, recycling, and labeling.

Regulatory Framework

Key Packaging Standards

China’s GB 4806.6-2016 standard mandates the safety and testing of packaging materials, ensuring they are non-toxic and environmentally safe.

| Regulation | Description | Applicability |

|---|---|---|

| GB 4806.6-2016 | Food-grade packaging material safety | Mattress vacuum packaging |

| ISO 9001 | Quality management in production | Manufacturing processes |

| RoHS Compliance | Restriction of hazardous substances | Export markets |

Export Compliance

Chinese mattress manufacturers shipping internationally often adhere to additional certifications like CE (Europe) or CFR Title 16 Part 1633 (USA), ensuring the packaging aligns with destination regulations.

Recycling Mandates

China also emphasizes sustainable practices. Vacuum packaging materials should either be recyclable or biodegradable to minimize environmental impact.

How does vacuum compression packaging impact the lifespan of Chinese mattresses?

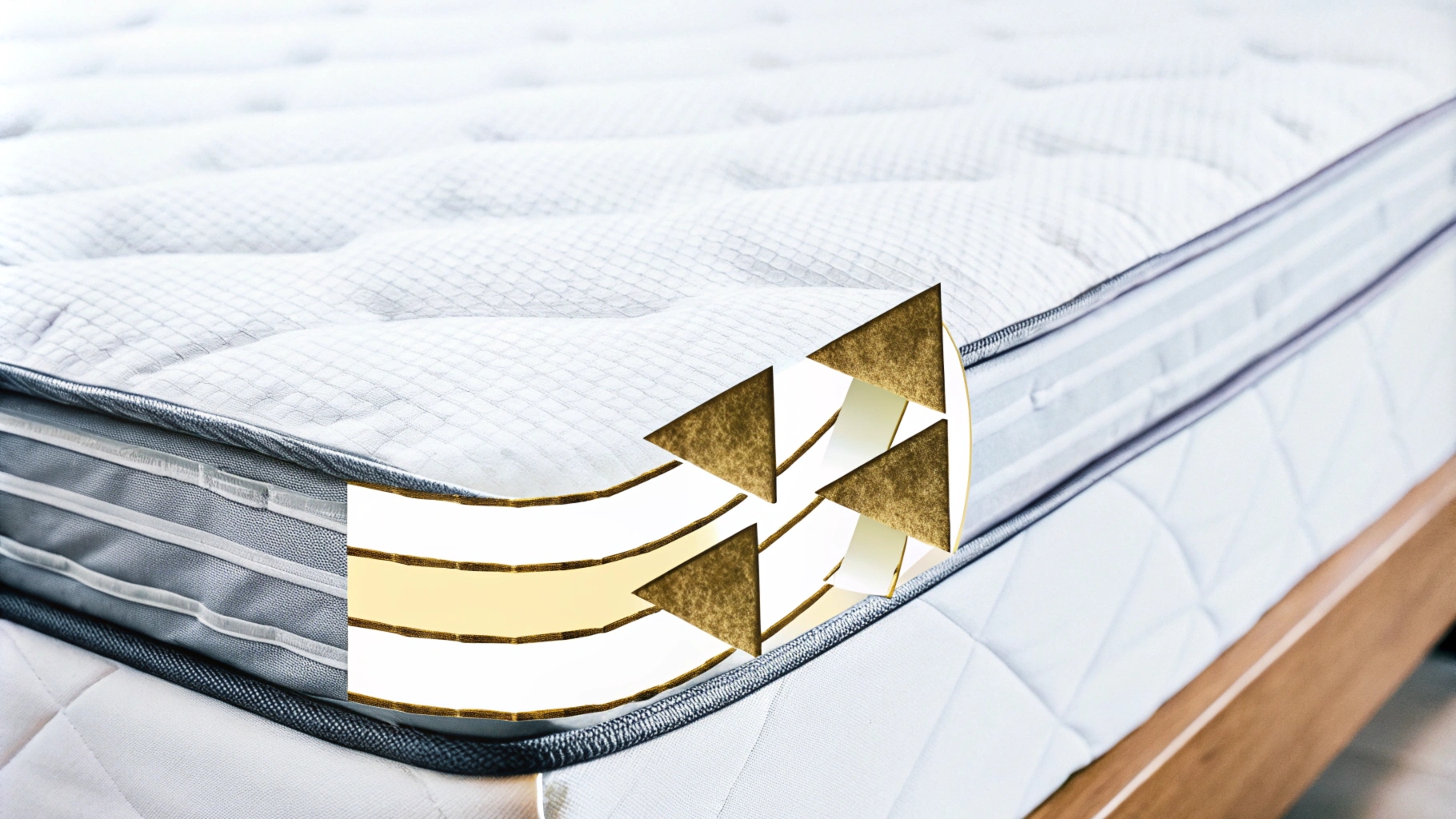

The compression process can influence the structure of mattress materials, particularly foam and springs.

When done correctly, vacuum compression does not harm the mattress but requires careful handling during storage and recovery.

Dive-Deeper: Effects on Mattress Longevity

Foam Mattresses

Foam mattresses are most commonly vacuum-compressed due to their flexibility. However, prolonged compression can lead to a condition called "compression set," where the foam fails to regain its original shape.

| Impact | Mitigation Strategies |

|---|---|

| Compression Set | Avoid extended storage periods (>6 months) |

| Moisture Retention | Use moisture-proof films |

Spring Mattresses

Spring mattresses face unique challenges during compression, as excessive force can deform the springs. Advanced vacuum technology minimizes this risk.

- Solution: Implement gradual decompression methods to allow springs to recover fully.

Best Practices for Recovery

End-users are typically advised to allow the mattress to rest for 24–48 hours after unpacking, ensuring it regains its full shape and comfort.

Conclusion

Vacuum compression packaging has transformed Chinese mattress delivery. It improves logistics, reduces costs, and ensures global accessibility, though proper handling and education are vital for long-term success.