Struggling to hit a supplier’s MOQ can kill a good deal before it even starts.

The typical MOQ for bed frames from China1 is between 50 to 200 sets, with some suppliers like us at DIKAPABED offering lower MOQs for flexibility.

%

MOQ matters. It decides whether a retailer like you can test a product or not. In my experience, small MOQs help build trust, reduce risk, and open doors to long-term partnerships. So in this post, I’ll walk you through MOQ expectations, frame pricing, how to judge quality, and how to check if your supplier is legit.

How much should a quality bed frame cost?

Margins disappear fast when the price of your product is off by even $10.

A quality bed frame2 usually costs $200 to $1,000, while factory direct prices can go as low as $55 to $90 per set.

Pricing depends on what materials and features you choose. Most local retail prices reflect multiple markups—by the time a bed frame reaches your customer, it may cost 3–4x what the factory charged. From what I’ve seen, metal bed frames usually cost less than solid wood or upholstery types. Here’s how the ranges break down:

Bed Frame Cost Breakdown

| Frame Type | Retail Price Range | Factory Bulk Price (DIKAPABED) |

|---|---|---|

| Metal | $200–$500 | $55–$70 |

| Upholstered | $300–$800 | $65–$90 |

| Solid Wood | $400–$1,000 | $80–$120 |

By ordering directly from us, you cut out layers of markup. That’s how some of our clients in Canada hit competitive prices while keeping profit margins intact.

How much does a bed cost on average?

It’s easy to price frames or mattresses alone—but combined costs tell the real story.

The average cost of a complete bed (frame + mattress) is between $500 and $2,000 depending on quality and size.

In my past projects with Canadian clients, we usually see this split: frame at $70 and mattress at $300–$500 for mid-market retail. That’s how most resellers keep final selling prices between $799 and $1,299 in stores.

If you separate sourcing—buying frames from China and mattresses locally or from another supplier—you control the cost structure better. Especially helpful when facing volatile shipping fees or tight market competition.

How to know if a bed frame is good quality?

Nobody wants a return request due to creaking frames or wobbly joints.

Good bed frames use thick metal or solid wood, support high weight, and carry certifications like SGS or EN747.

You don’t need to be an expert to spot a strong frame. I usually tell clients to inspect four areas:

Quality Inspection Checklist

| Feature | What to Check |

|---|---|

| Frame Materials | Metal (1.0mm+ thickness) or solid hardwood |

| Weight Support | 500–600 lbs minimum support |

| Slat System | No bending/slipping, 12+ thick slats |

| Certifications | SGS, EN747, or ISO9001 |

If your frame ticks these boxes, it’ll hold up well—even in high-turnover retail environments. And yes, we build our frames this way by default.

What to look out for when buying a bed frame?

Even seasoned buyers miss small things that turn into big complaints.

When buying bed frames, watch for size mismatch, weak joints, low-quality paint, or incomplete fittings.

Some buyers only ask for photos. But images can hide issues like poor welding, thin coatings, or bad packaging. My advice? Always request a sample before your first container order.

What to Watch Before Buying

| Risk Factor | What to Ask or Check |

|---|---|

| Size Compatibility | Match mattress standards in your country |

| Material Finish | Check for rust-resistant powder coatings |

| Weld Quality | Inspect corners and joints closely |

| Packaging | Confirm KD packaging, carton thickness |

At DIKAPABED, we use 5-layer cartons and bubble wrap inside. That’s why breakage rate is under 1%.

How do I verify a supplier’s credibility before placing a bulk order?

A pretty Alibaba page doesn’t guarantee real capacity.

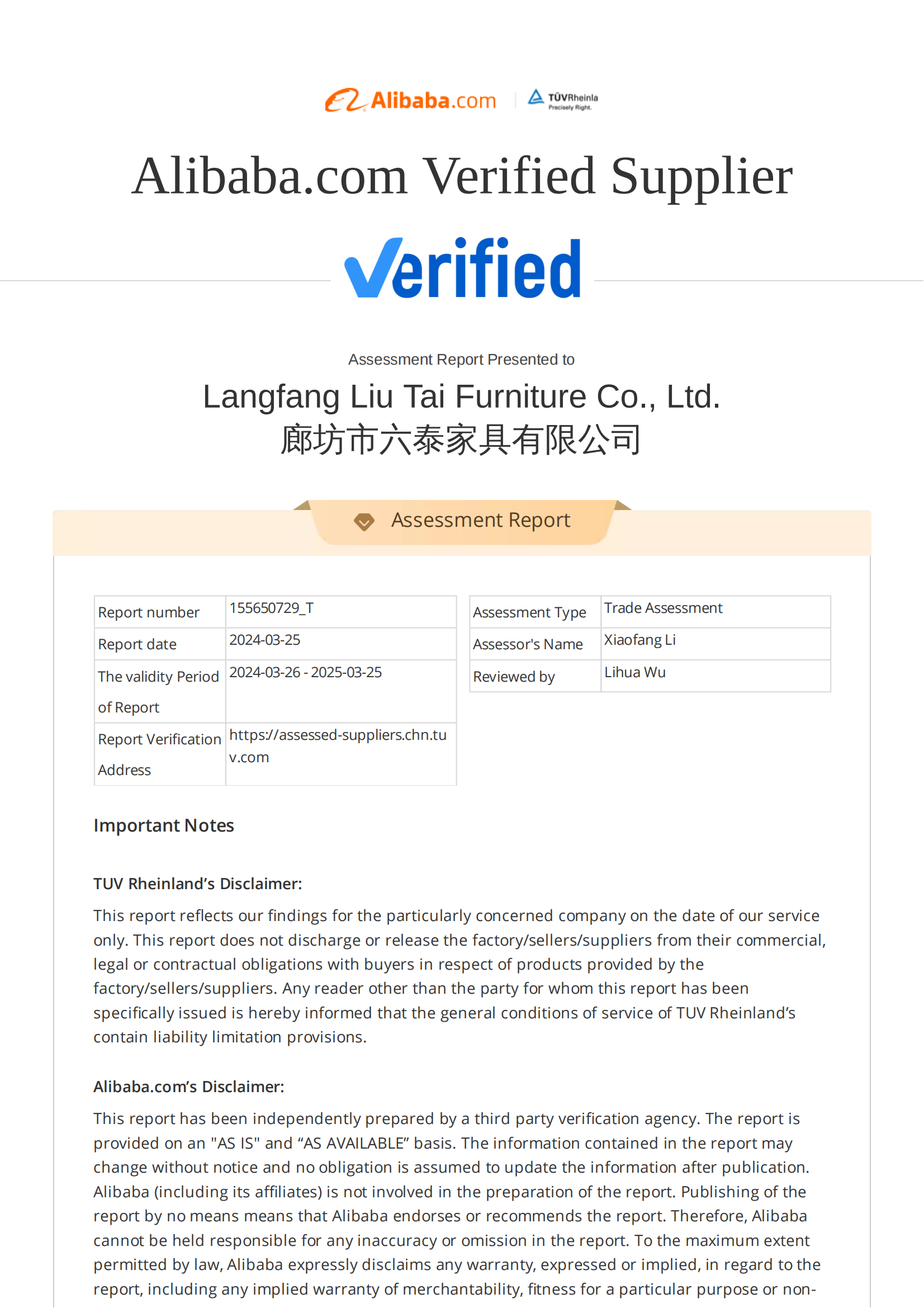

To verify a supplier, check business license, certifications, reviews, and ask for video calls or sample shipments before big orders.

I’ve seen retailers burned by ghost factories or fake certificates. If you’re sourcing bed frames in bulk, here’s what I recommend:

Supplier Credibility Checklist

| Verification Step | What to Do |

|---|---|

| Business License | Request local registration documents |

| Third-Party Reviews | Use Alibaba, Google, Trustpilot |

| Factory Visit / Video | Do a video walkthrough or send agent |

| Trial Orders | Start with 1–2 models, small volume |

| Secure Payment | Use Trade Assurance or LC |

If they dodge any of these, walk away. You don’t want a lost container over avoidable risks.

What certifications should B2B bed suppliers provide?

Certifications are more than paper—they show what level of business you’re dealing with.

A serious supplier should have SGS, EN747, FSC, and optionally BSCI or ISO9001.

For Canadian retailers, having EN standards is non-negotiable. SGS testing ensures structure stability, FSC proves wood sourcing is ethical, and EN5852 proves flammability resistance for upholstered parts.

At DIKAPABED, we provide:

- SGS: structural and material testing

- EN747: bunk bed safety

- FSC: wood traceability

- BSCI: ethical workplace audits

- EN5852: fire retardant tests

We offer copies before you confirm any order. You can even add your own logo or request neutral packaging with compliance symbols.

Who makes the best quality bed frames?

Many top brands don’t make their own beds—they just label them.

Brands like Thuma, Article, and Blu Dot are known for quality; we match their structure at lower cost for B2B.

%

Thuma’s solid wood platform bed goes for $995 retail. Blu Dot’s steel + foam frame is $1,199. But I’ve reverse-engineered their specs: most use 25mm pine slats, powder-coated steel, and 4-point welded brackets.

We use similar specs, same frame strength, same testing. What’s different? You get it at $70–$90 instead of $1,000+. And you sell it under your own brand.

Conclusion

Chinese bed frame MOQs start at 50–200 units. If you source smart, you’ll get retail-grade quality at 1/5 the price.